Food Production Inspection System from Bizerba. This page will look at Metal detectors, X-ray inspection systems and Vision inspection systems.

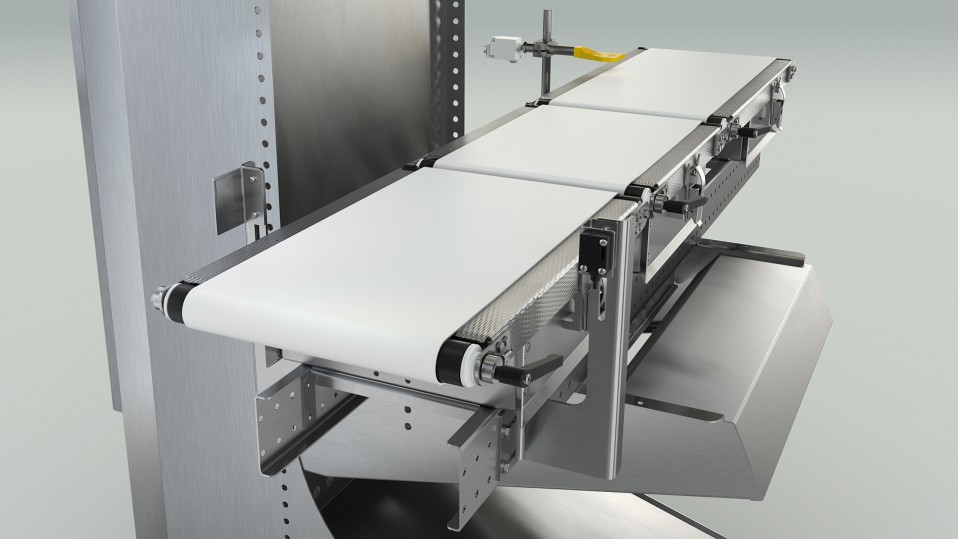

Food Production Inspection System – Checkweigher

Used with High Precision Checkweighing Systems. Food production inspection systems guarantee a fantastic level of security and food tracability to your production line. Checkweighers will reject with pushers any over weight and under weight packages as they pass down the production line. This is generally the first check after packaging.

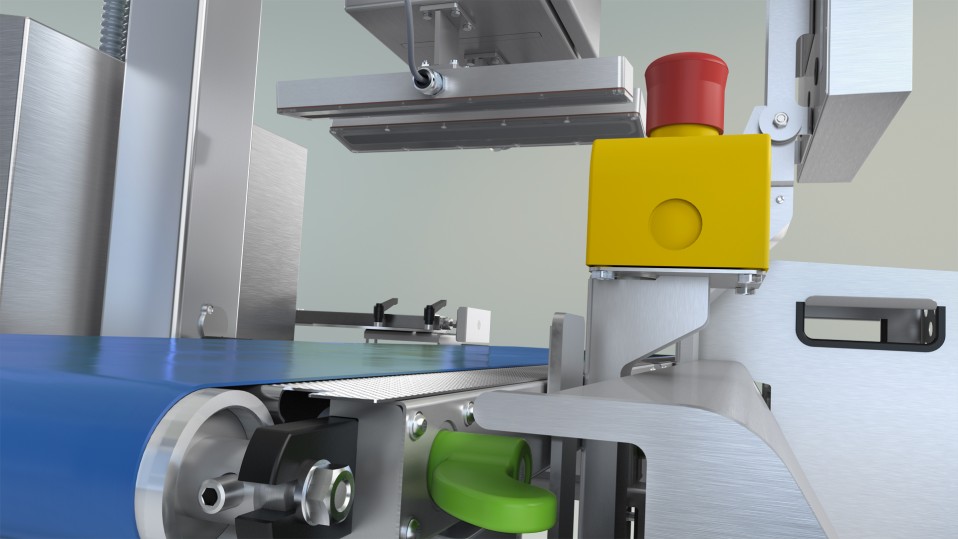

Food Production Inspection System – Metal Detector

Secondly the packages will then move through a metal detector. Any ferrous or non ferrous metals in the packages, again the packages will be rejected with pushers. Due to the limitations of metal detectors most food manufactures are now turning to X-Ray inspection systems.

Food Production Inspection System – X-Ray Inspection

Also the X-Ray inspection system is now becoming the norm on food production lines. In the past the only contaminant that would trigger a recall would have been metal. Now food producers must guarantee that there are no plastics, glass, metals, rubber even stones or bones in the pack. The X-Ray food inspection system from Bizerba will identify all of those and even identify incorrect densities within the packages.

Food Production Inspection System – Vision Inspection

In addition the third step in the food production inspection system is the vision inspection systems. These systems record every package that passes through, takes a digital image for future reference when required. With pushers it will also reject incorrect labelling, package seals and sell by dates. They will also identify QR code technology and will read and ensure that everything is within the set criteria.

In conclusion, if you want the very best and most reliable production line inspection system the set up would be as follows. A Dynamic checkweigher machine followed by an X-Ray inspection system then it would pass finally through the vision inspection system. Three layers of protection that even the human eye would not be able to identify.

Contact Bizerba today for a free site survey or a no obligation consultation visit.